Kakor hjälper oss att leverera våra tjänster. Genom att använda våra tjänster, tillåter du vår användning av kakor.

3D-svetsning

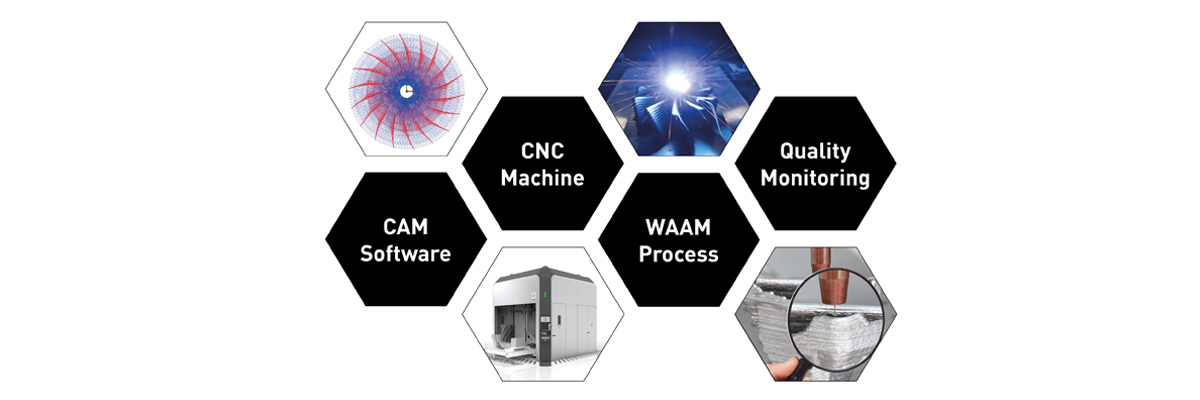

3DMP® Technology

3DMP® technology combines the WAAM process with a robust CNC machine system, integrative CAM software, and process-related quality monitoring.

Benefits

- Higher deposition rates

- Greater diversity of materials

- Improved mechanical properties

- Large volume parts

- Economically efficient for batch sizes of 1

- Reduction of manufacturing costs by up to 60%

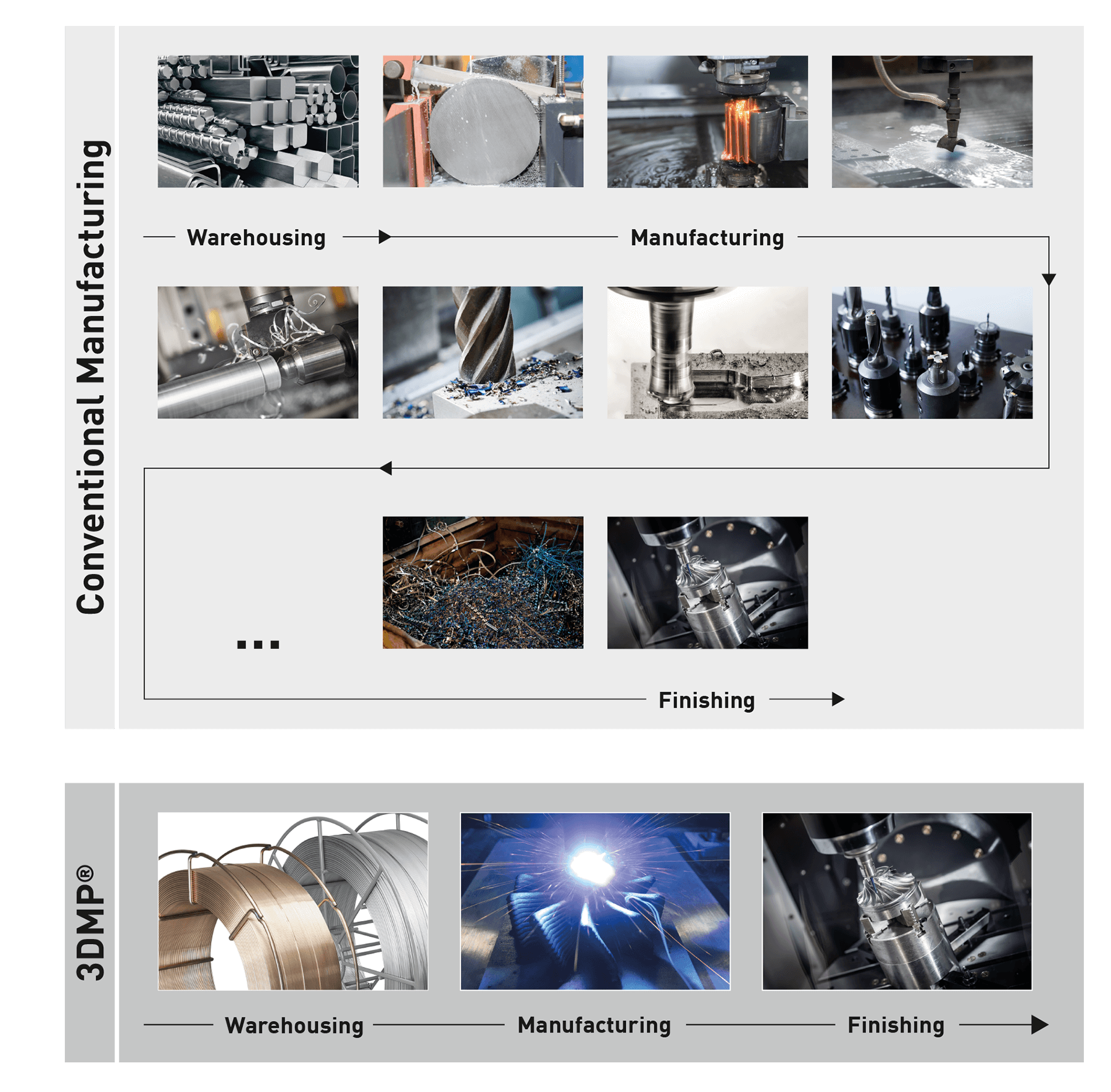

- Reduced number of manufacturing steps

- Maximum material utilization

- Outstanding design freedom

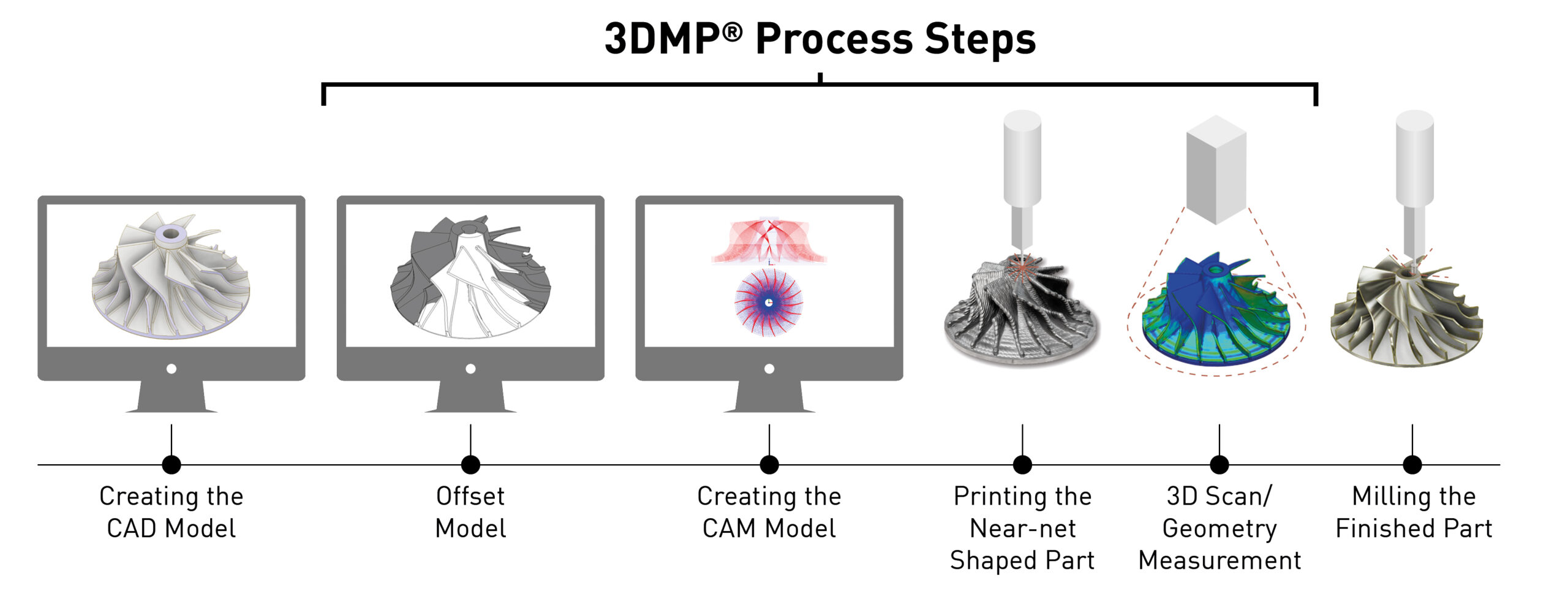

The 3DMP® Process Chain

3DMP® combines the reliable arc welding method with the CAD data of metal parts to be produced. Custom software converts CAD data into individual printing layers (CAM models). The process includes:

- Automatic blank printing

- 3D scanning for quality control

- Milling of the finished part

Wire Instead of Powder

3DMP® uses wire as the starting material, offering:

- Nearly 100% material utilization

- Easy storage

- Low material costs

- Easy handling

- Optimum processability

- Greater diversity of materials