Cookies help us deliver our services. By using our services, you agree to our use of cookies.

BÜLTMANN Production lines

In order to ensure automatic sequences and production processes, preferably unmanned, various machines are suitably interlinked and optimally aligned.

The interlinking of machines ensures a higher productivity with reduced manpower and minimum space requirement, as e.g. intermediate storages are dispensable.

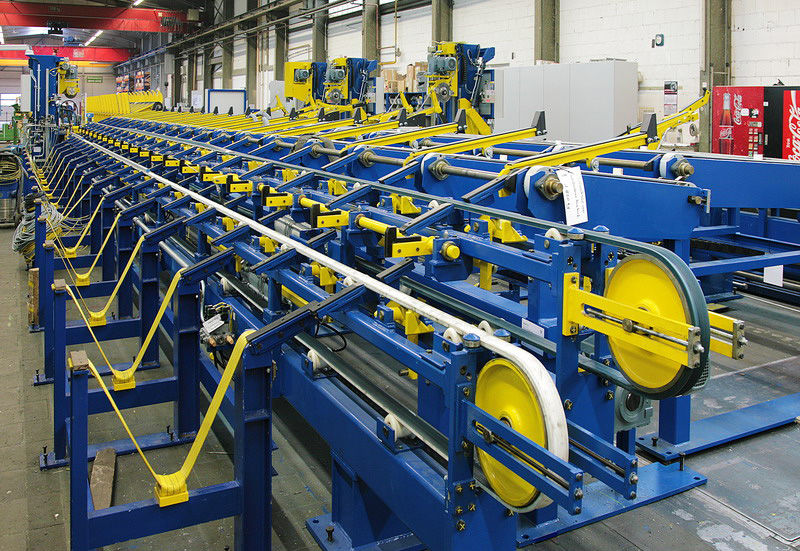

Production line for testing, sawing, chamfering and packing of tubes

The tubes are automatically separated, tested, sawn, chamfered and air-cleaned. Then the tube ends are plugged and the finished tubes are packed in boxes or hexagon bundles.

![]()

|  |  | |

| Chamfering equipment | Tube transport system to the chamfering equipment, the scrap cradle and the sawing unit | Cross transport system | |

|  |  | |

| Arms for feeding the tubes into the sawing unit | Charging cradle with cross conveyor to the separation system | Tube separation system | |

|  |  | |

| Sawing unit and abrasive cutting unit | Sawing unit and abrasive cutting unit | ||

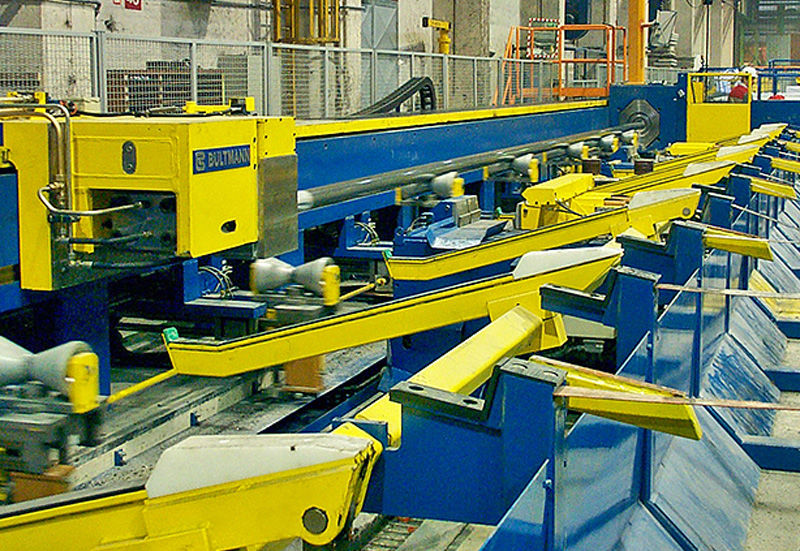

Tube production lines featuring interlinked machines

Amongst others separation unit, pointing machine, drawing machine, chipless cutting equipment, 10-roll tube straightening machine, cutting and testing equipment, for example for precision steel tubes

|  |  |

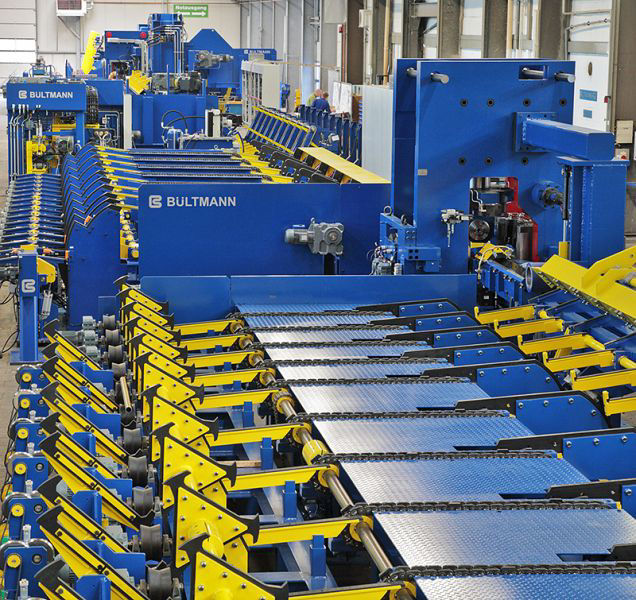

Bar production line

| ||

| Detail of a complete line with straightening machine for hot-rolled bars, peeling machine, 2 roll straightener, chamfering and testing equipment | ||

| ||

| Bar production line with separation unit, peeling machine and 2-roll straightener | ||

|