Kakor hjälper oss att leverera våra tjänster. Genom att använda våra tjänster, tillåter du vår användning av kakor.

EBNER Presshärdning

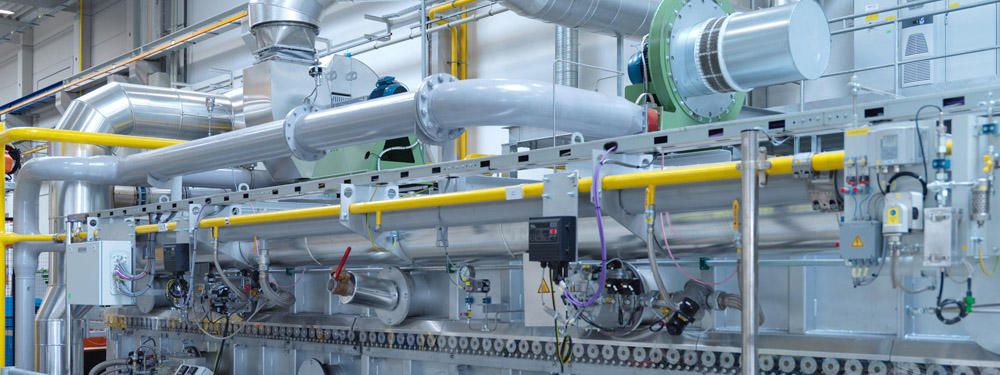

HOTPHASE Furnaces. Technology for press hardening.

Only the latest technology meets the high quality standards of automotive suppliers. EBNER HOTPHASE furnaces are effi cient, precise, and durable. Complex structural parts with tensile strengths in excess of 1500 MPa set new standards in lightweight automotive design, well as in crash test performance.

Our HOTPHASE furnaces offer:

- the highest possible degree of standardization

- the best possible fl exibility in design

- the highest quality of equipment and service

- durable mechanical and automation systems

- a wide variety of furnace dimensions are possible

- a wide variety of heating systems may be employed

- a wide variety of furnace atmospheres may be programmed

- the highest fl exibility and precision during production

- the most precise temperature and atmosphere control

- exact maintenance of the temperature of the blanks

- the shortest possible cycle times

- the lowest possible consumption

- the greatest possible facility availability

- straightforward operation and maintenance

- the best spare part and service support

Technical highlights:

- SiSiC radiant tubes: the best performance, paired with long service life and low maintenance (regular rotation of the tubes is not required)

- Standard roller bearings in the cold section: no cooling of bearings required

- Simple roller seal design: ensures the cleanest and most economical furnace atmosphere

- Centering roller table for blanks: straighforward, automatically reproducible positioning of blanks

- Automatic valve stand: switches process atmosphere supply economically and accurately

- Automation and analysis: fully-automated supervision and control of the furnace atmosphere