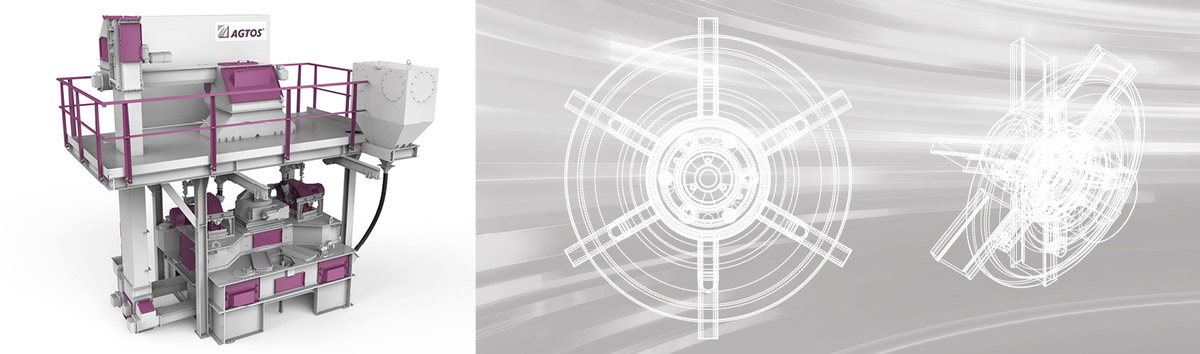

AGTOS Bläster med roterande bord

The AGTOS Product Range

Our standard line-up of rotary table blast machines include table diameters ranging from 1100 mm to 2200 mm.

The choice of the appropriate machine concept depends on your work pieces, the required level of performance and last but not least on your specific needs regarding an optimized production process.

Our team of experts welcomes your detailed questions and looks forward to helping you!

Operation

When processing work pieces in batch mode, the rotary table stops, the doors open and several work pieces are then placed on the rotary table. The door closes and the work pieces are rotated into the blasting zone and then cleaned.

In continuously operating rotary table blasting units, the work pieces are continuously blasted in the rear area of the rotating table. Loading and unloading take place in the front of the machine. Special vestibules seal the loading and unloading areas of the rotary table and prevent the escape of stray abrasive.

Other rotary table machines operate in so-called duplex mode. While one batch is blasted, another is loaded or unloaded. In duplex machines, two batches are located in the machine at the same time.

In satellite rotary table blasting machines, work pieces are blasted on rotating platforms arranged in a radial pattern. Machines such as these are usually operated in indexing mode.

In all of these different machine types, the blasting abrasive is continuously cleaned, recirculated and reused. An abrasive metering device feeds the cleaned abrasive from the abrasive storage bunker to the high-performance turbines.

A fan unit creates the partial vacuum necessary to maintain dust-free operation of the blasting unit. Extracted air is cleaned in a special filter unit.

Capabilities and applications

Conventional rotary table blast machines are usually loaded manually. The machines are most frequently used to batch clean cast or die-cast work pieces and to roughen the surfaces of work pieces prior to coating.

In automated lines, primarily in the automotive industries, satellite rotary table blasting machines often include integrated robotic handling devices. Such a configuration is used to harden the surfaces of transmission components, for example.