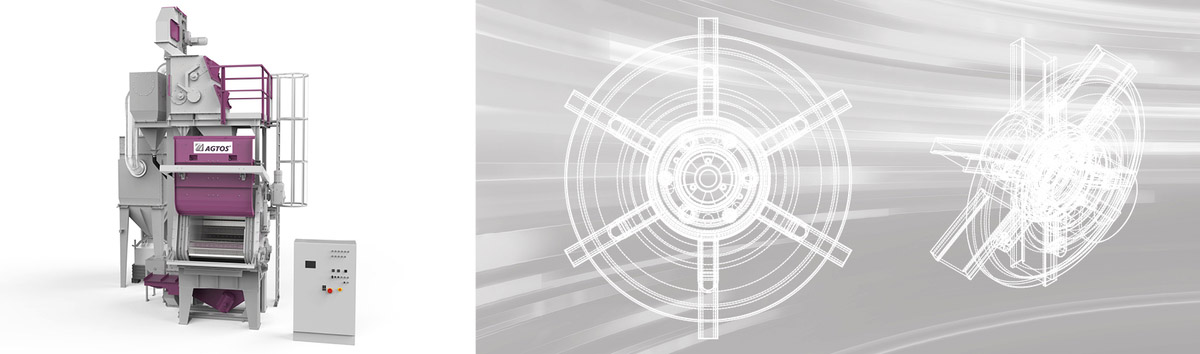

AGTOS Trumlingsbläster

The AGTOS Product Range

Our standard program of steel mill tumble blast machines (Model MR) will have filling volumes ranging from 180 to 1550 liters.

The choice of machine depends on the volume and the batch weight of the work pieces to be blasted. In addition, other parameters such as a work piece’s geometry, material and temperature should be considered when selecting a tumble blast machine.

In the event that a standard model does not meet your surface preparation needs, we will develop a tailor-made blast machine concept for you.

Our team of experts welcomes your detailed questions and looks forward to helping you!

Operation

The loading device loads work pieces directly into the blast machine from containers, pallets or so-called charging baskets. The work pieces slide through the open loading door and onto the advancing caterpillar tread.

The loader subsequently returns to its initial position. The blasting process begins after the loading door is automatically closed and locked. After the blasting period ends, the door opens automatically. The freshly blasted work pieces are removed in sequence by a take-off conveyor, or by emptying them directly into containers provided by the customer.

The blasting abrasive is continuously cleaned, recirculated and reused. An abrasive metering device feeds the cleaned abrasive from the abrasive storage bunker to the high-performance turbines.

A fan unit creates the partial vacuum necessary to maintain dust-free operation of the blasting unit. Extracted air is cleaned in a special filter unit.

Capabilities and applications

The tumble blast principle has been recognized for decades as the most effective blasting process for removing sand, scale and burrs from heavy or sharp-edged mass production parts that require the robust steel mill design found in our Model MR tumble blast machines. Mounting screws secure the machine’s steel plates to links in the caterpillar tread. These links are then joined together with appropriate connecting elements. The tumbling motion of the mill ensures that work pieces are exposed to the abrasive stream during the entire blasting period.

Machines of this kind can be filled and emptied in a variety of ways: with an automated loading device and take-off conveyor, or with other equipment already integrated in the rest