AGTOS Single-disc blasting wheel 3.6

Product description

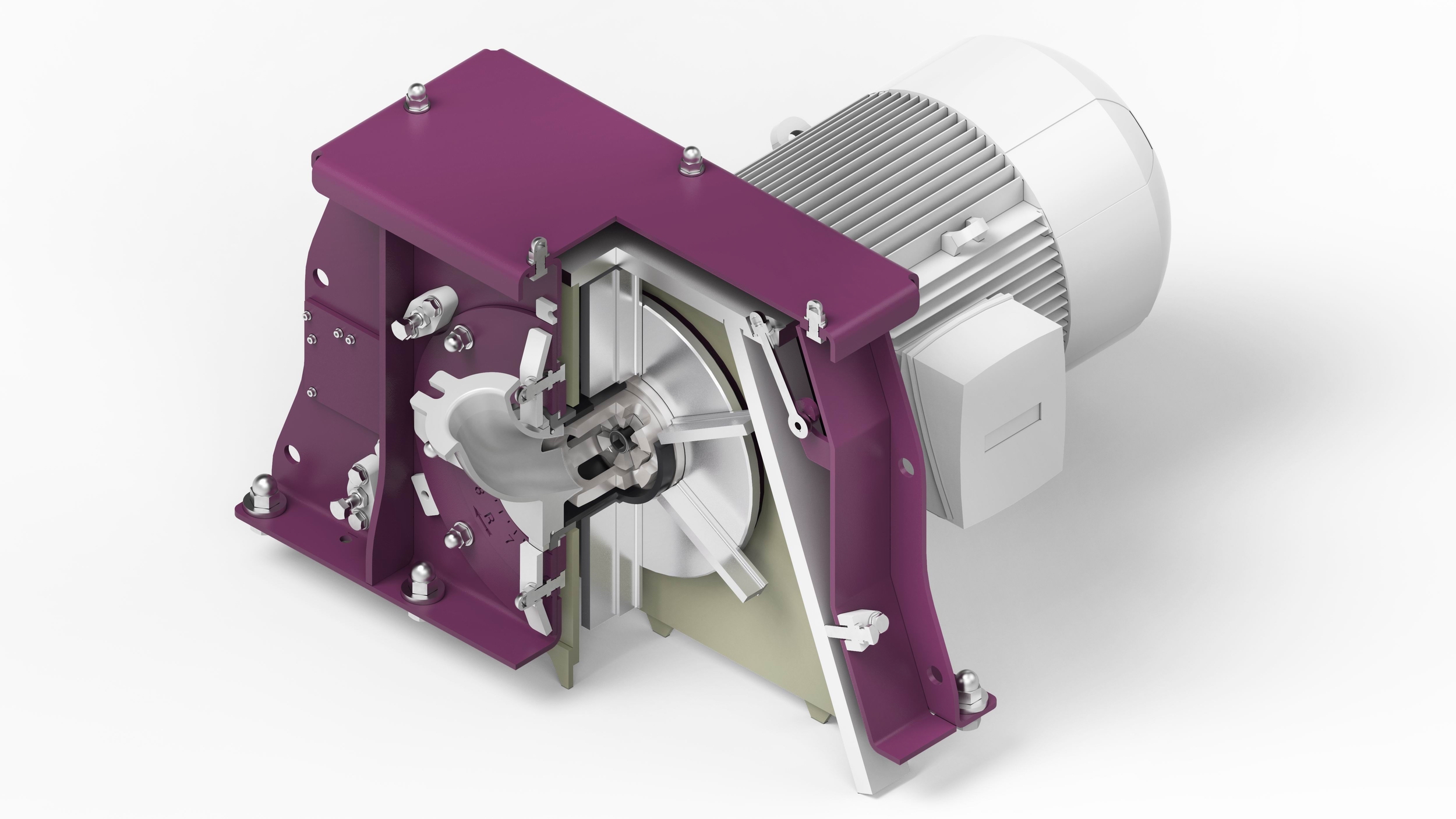

This aggregate is a single-disc blasting wheel with six pluggable blades. We offer these high-performance turbines with a shot blasting wheel diameter of 330 and 380 mm. Motors up to 22,0 kW provide drive mechanism.

The advantage of single-disc blasting wheels lies in the fact that fewer parts subject to wear are present than in double disc wheels. This means less work required for assembly and lower costs for maintenance and repairs. We will be glad to explain the difference to you in detail.

The blades are inserted in the carrier disc from the middle. An additional clamping disc covers the insertion opening and arrests the blades.

All internal parts of the turbines such as blades, impeller, conduit sleeve and the discs are made of wear-resistant material. Different variants are available and can be selected to match your use case.

The turbine housing consists of wear-resistant manganese steel and is protected from the inside by additional replaceable plates of a similarly wear-resistant tool steel.

The most important wear parts of the blasting wheel can be removed either through the removable cover on the turbine housing or through the assembly opening on the side of the turbine housing. This saves assembly effort and costs.

The favourable flow characteristics of our AGTOS-high-performance turbines assure a high through put of blasting abrasive and with it outstanding blasting results. The Hot Spot, the surface being bombarded with blasting abrasive, is long and evenly thick, which produces the best blasting results.

Wear parts made of hard metal

For applications with very aggressive abrasive and high wear, we are also offering the wear parts for our high performance turbines 3.6 made of hard metal. The life times of the wear parts can thus be up to 10 times longer. This ensures a continuous production and minimizes maintenance and service times.

In order to enable our customers to use up already existing wear parts before changing to hard metal parts, we are also offering the stepwise change of material. We would be glad to explain the different options.

AGTOS high-performance turbines are not just mounted on new machines. To date, after retrofitting of existing shot-blasting machines with the AGTOS-system, improvements in blasting performance have always been achieved.

Along with the replacement of complete turbines, we offer various refit sets under the title „AGTOS-Inside“. This option installs the internal components of AGTOS-turbines in existing, still intact turbine housings from other manufacturers. This can decisively improve blasting results. At the same time, it reduces costs, since parts that have not yet worn out are used up first. For this variant, structural prerequisites are needed that must first be tested. Please contact us.