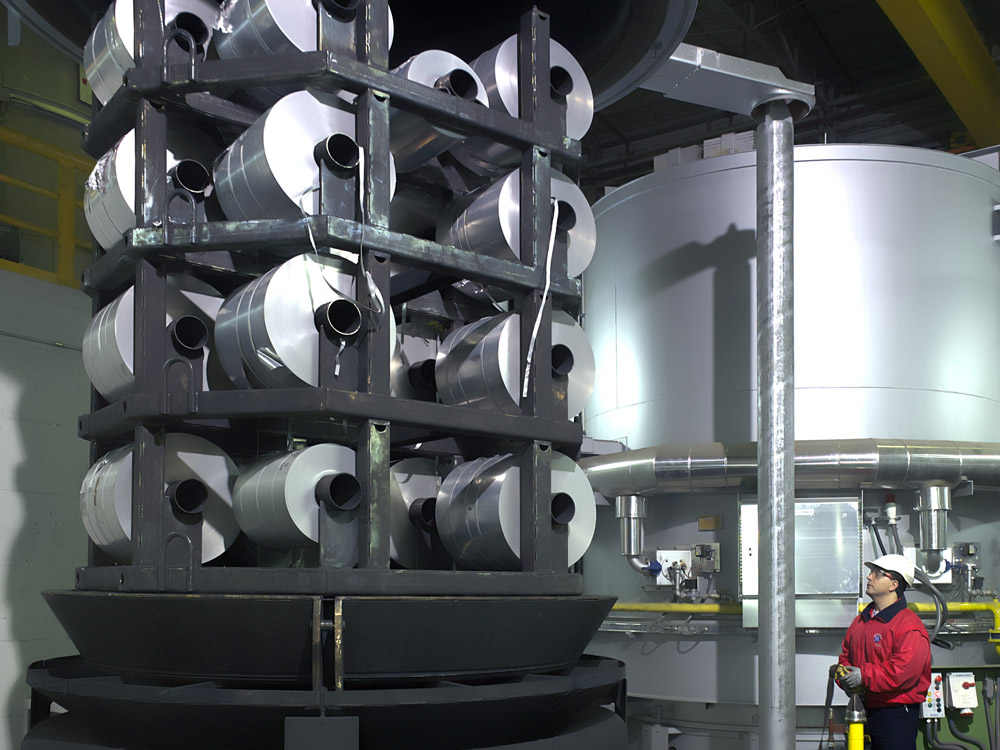

HICON bell annealers for high-capacitance foil

HICON bell annealers for high-capacitance foil.

Aluminum foil for the electronics industry must fulfill the very highest quality requirements. Only the highest purity aluminum is used for manufacturing high-capacitance foil.

The purity of the aluminum increases depending on the operating voltage. For low voltage applications grade AI3N8 is sufficient, while high voltages require AI4N (AI 99.99 %).

An extremely pure process atmosphere is used during the anneal to achieve a uniform Al2O3 layer on the foil surface, which in turn benefits tunnel etching during subsequent processes. The material is processed at annealing temperatures between 550 °C and 620 °C, and the atmosphere dewpoint must be below -30 °C.

To fulfill these strict criteria the anneal has to take place in a furnace with a retort that is both gas-tight and vacuum-tight. A HICON bell annealer is ideal for this application.

HICON bell annealers are distinguished by the following features:

- Metallic surfaces designed for medium vacuum

- Flexible heating-up and cooling gradients in vacuum or process atmosphere

- Gas-tight and vacuum-tight workload space.