EBNER Bell Annealer HICONSABER

![]()

HICONSABER fully automatic bell annealer facility with HICON/H2 technology

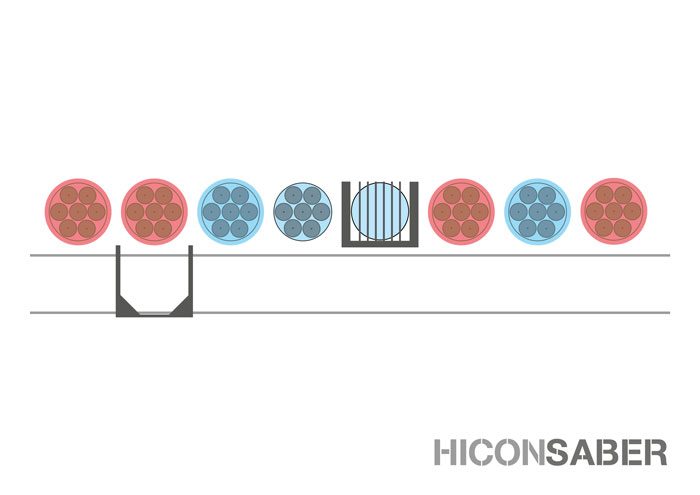

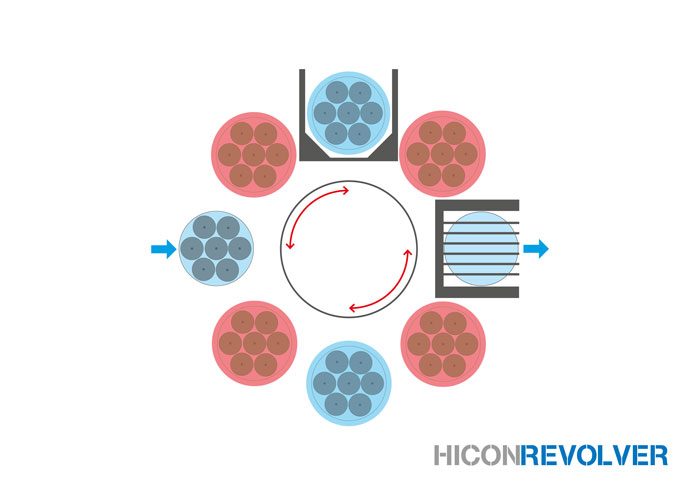

SABER – Safe fast Automatic floor based Bell annealer charging and lifting Equipment Robot

Use of the SABER fully automatic handling system significantly increases the throughput capacity, workplace safety and process reliability at an EBNER bell annealer facility, even as it reduces maintenance and personnel costs. The facility requires no overhead crane, and can be installed in lightly-built shop structures. The new bell annealer design is economical to operate, even with small batch sizes and low throughputs. Its modular design allows it to be easily expanded by adding additional workbases.

![]()

![]()

HICONSABER – the advantages of a fully automatic bell annealer facility with an integrated charging system

No overhead crane require

- Allows increased stacking heights

- May be installed in shop structures with small foundation footings

Increased workplace safety

due to protected area for automatic operation

Reduced personnel costs

- Allows increased stacking heights

- May be installed in shop structures with small foundation footings

No overhead crane require

for facility operation, may reach up to 50 %

- Automatic positioning of heating bells, cooling bells and inner covers

- Charges are automatically placed on the work-base and decharged

- Processing may take place without an operator (night and weekend shifts)

Precise handling and exact positioning of bells, covers and charges

in comparison to overhead crane

- Increased service life of facility components

- Reduced maintenance work

- High degree of process safety

- Reduced maintenance costs

New facilities may be installed in existing workshop structures

with low heights, as with the automatic charging system heating and cooling bells may be lifted all the way up to the shop roof for transport.

Integration of upstream and downstream processing steps

into the fully automatic operation of the facility (e.g. strip coils from the rolling mill or wire coils from the drawing mill)

Up to a 15 % increase in facility throughput

- Up to a 50 % reduction in workbase downtimes

- Increased clear inside heights at each workbase in comparison to facilities with an overhead crane

- Increased facility running time and reduced downtime

Applications

Heat treatment of steel, copper base metal or aluminum, with the following types of semi-finished products:

- Wire coils in single or multiple stacks

- Strip coils in single stacks

- Tube coils in single stacks (for copper tube coils, facilities may be equipped with fully automatic tube purging systems to achieve the best possible interior surface finishes)

![]()

LAYOUTS

EBNER HICON/H2 technology

Thanks to high convection and a 100 % hydrogen atmosphere, semi-finished products annealed in an EBNER HICON/H2 bell annealer have the best possible mechanical properties, uniform microstructures and the cleanest possible surfaces.

17 % reduction in annealing costs per ton

through the use of hydrogen as a process atmosphere

40 % hydrogen savings

through process atmosphere recycling

25 % energy savings

through the use of hydrogen as a process atmosphere

6,5 % reduction in fuel gas consumption

due to the low density of hydrogen and shorter heating times