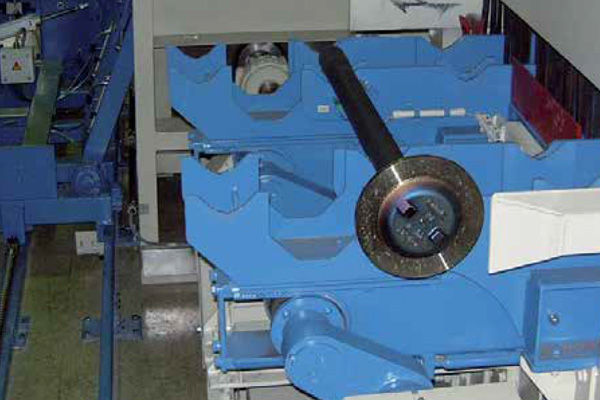

AGTOS Walking beam shot blast machine

The AGTOS Product Range

The choice of machine depends on the quantity and the weight of the workpieces to be blasted. Furthermore, the workpiece parameters to be blasted, such as geometry, material, and temperature of the workpieces has to be taken into account.

Please send us your detailed enquiry.

Our experienced team will be glad to assist you.

Application areas

Application areas of AGTOS walking beam shot-blasting machine (type HB)

Sensitive workpieces are transported through the shot-blasting machine using the walking beam principle. Each workpiece is individually lifted, cycled onward and gently set down.

Industrial process

The industrial process of the walking beam shot-blasting machine

The workpieces are placed manually, or reach the the shot-blast machine by conveyor belt and automatically separated.

The blasting process starts as soon as a workpiece reaches the inlet threshold. The workpiece moves gently through the blast machine automatically, and is fed manually or automatically to the next processing step after the blasting process.

The abrasive keeps circulating and is cleaned to allow continuous use. An abrasive dosing device is used to transport the cleaned abrasive from the storage hopper to the high performance turbine.

A fan unit creates the partial vacuum necessary to maintain dust-free operation of the shot-blasting-machine. The extracted air is cleaned with an on-site filtering facility.

Video

Product data sheet